Large reduction ratio, high production efficiency;

Less consumption of wearing parts, low operating costs;

Pyramid broken, perfect of product shape;

Hydraulic protection and hydraulic pressure cavity clear high degree of automation to reduce downtime.

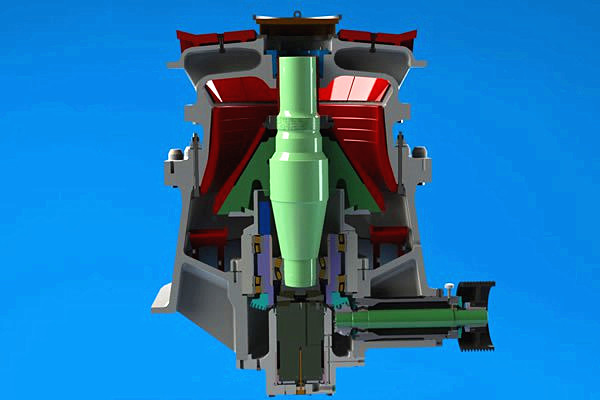

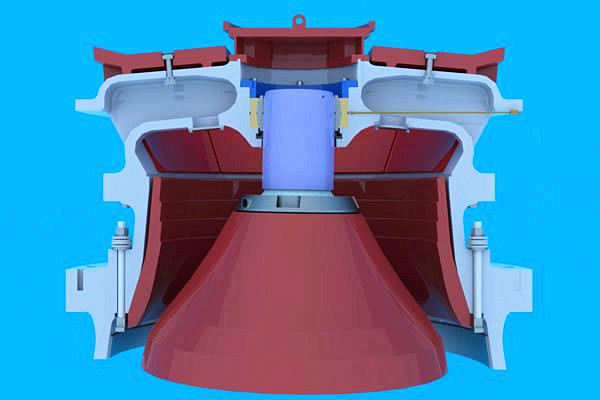

Single cylinder hydraulic cone crushers are patented hydraulic crushing machines widely applied in a variety of industries. The powerful portable crushers can be used for the intermediate and fine crushing of all kinds of materials, such as iron ore, non-ferrous metal ores, granite, limestone, quartzite, and sandstone. This series of single-cylinder hydraulic cone crusher uses a combination of high quality crushing machinery parts and has automatic hydraulic and electric intelligent control technology.

To meet individual demands, we can supply single cylinder cone crushers with power between 90 and 520kw, for crushing materials with size from 30 to 560mm.

Technical Parameter

SCS-Crushers | Max motor | Max Feed size | Nominal capacity in t/h with crusher at CSS mm | ||||||||||

(kw) | (mm) | 19 | 25 | 32 | 38 | 44 | 54 | 60 | 64 | 70 | 83 | ||

SCS90 | 90 | EC | 240 | 92-115 | 107-168 | 121 | |||||||

C | 200 | 70 | 82-128 | 96 | |||||||||

SCS132 | 132 | EC | 360 | 126 | 147-230 | 165-310 | 183-344 | 214 | |||||

C | 300 | 116-145 | 132-254 | 152-285 | 169-264 | ||||||||

MC | 235 | 91 | 106-166 | 124-232 | 139-261 | 154-241 | |||||||

SCS220 | 220 | EC | 450 | 282-353 | 313-563 | 365-456 | |||||||

C | 400 | 239-299 | 269-484 | 298-448 | |||||||||

MC | 300 | 195 | 228-342 | 256-461 | 284-426 | ||||||||

SCS315 | 315 | EC | 560 | 368-460 | 428-856 | 465-929 | 489-978 | 525-1050 | 604 | ||||

C | 500 | 318 | 353-618 | 411-823 | 446-892 | 469-822 | 504-631 | ||||||

SCH-Crushers | Max motor | Max Feed size | Nominal capacity in t/h with crusher at CSS mm | ||||||||||

(kw) | (mm) | 4 | 10 | 19 | 32 | 38 | 44 | 51 | 57 | 64 | 70 | ||

SCH90 | 90 | EC | 135 | 46 | 58-99 | 76-128 | |||||||

C | 90 | 43-53 | 54-103 | 61-118 | |||||||||

M | 65 | 38-74 | 48-59 | ||||||||||

MF | 50 | 40-71 | |||||||||||

F | 38 | 27-34 | 32-57 | ||||||||||

EF | 29 | ||||||||||||

SCH132 | 132 | EC | 185 | 80-161 | 91-182 | 115-208 | |||||||

C | 145 | 76-152 | 86-173 | 109-150 | |||||||||

MC | 115 | 57 | 72-152 | 82-184 | |||||||||

M | 90 | 64-84 | 80-152 | 91-154 | |||||||||

MF | 75 | 65-106 | 81-126 | 92 | |||||||||

F | 50 | 54-88 | 68-105 | 77 | |||||||||

EF | 35 | ||||||||||||

SCH220 | 220-250 | EC | 215 | 122-276 | 139-313 | 192-384 | |||||||

C | 175 | 117-292 | 133-332 | 183-229 | |||||||||

MC | 140 | 113-282 | 128-320 | ||||||||||

M | 110 | 136-298 | 154-339 | ||||||||||

MF | 85 | 114 | 144-263 | 163-299 | |||||||||

F | 70 | 96-176 | 120-221 | 137-251 | |||||||||

EF | 38 | ||||||||||||

SCH315 | 315 | EC | 275 | 190-338 | 216-464 | 272-605 | 298-662 | 328-551 | |||||

CX | 245 | 187-374 | 212-519 | 268-654 | 293-521 | 323-359 | |||||||

C | 215 | 209-510 | 263-643 | 288-512 | 317-353 | ||||||||

MC | 175 | 198-520 | 249-499 | 273-364 | |||||||||

M | 135 | 240-500 | 302-403 | ||||||||||

MF | 115 | 252-450 | 318-363 | ||||||||||

F | 85 | 256-400 | 323 | ||||||||||

EF | 65 | ||||||||||||

SCH520 | 520 | EC | 300 | 544-968 | 601-1070 | 658-1172 | 725-1291 | 782-1393 | 849-1512 | 906-1331 | |||

C | 240 | 406 | 525-1018 | 581-1125 | 636-1232 | 700-1357 | 756-1464 | 820-1461 | 876-1286 | ||||

MC | 195 | 380-440 | 492-954 | 544-1055 | 596-1155 | 657-1272 | 708-1373 | 769-1370 | 821-1206 | ||||

M | 155 | 400-563 | 519-953 | 573-1054 | 573-1544 | 692-1271 | 745-1372 | 810-1248 | 865-1098 | ||||

MF | 100 | 407-716 | 527-928 | 582-942 | 582-942 | 702 | |||||||

F | 90 | 141-704 | 535-912 | 592-857 | 592-857 | ||||||||

EF | 80 | 352-598 | 455-775 | 503-728 | 503-728 | ||||||||

EF=Extra Fine,F=Fine,MF=Medium,M=Medium,MC=Medium Coarse,C=Coarse,CX=Coarse Xtra,EC=Extra Corase | |||||||||||||